“"A zipper alone cannot make a garment, but it can ruin one." The quality of a zipper is crucial to clothing; if the zipper's closure function malfunctions, the garment is likely to end up in the trash bin. Compared to other auxiliary materials, zippers have the shortest history, yet they have undeniably become one of the key components of clothing, not only enhancing the structural plasticity of garments but also adding to their aesthetic appeal.

Zippers are accessory products of clothing, but they possess a separate industrial system and industrial chain, demonstrating a high degree of independence. The development of the Chinese national zipper industry has spanned a century, yet its industrialization, clustering, and modernization have only progressed for more than four decades. Following the pace of Made in China, Chinese zippers have continuously evolved, innovating, upgrading, and advancing, making their due contributions to the high-quality transformation of China from a major garment producer to a powerful one.

01

Zippers Usher in a New Era of Modern Clothing

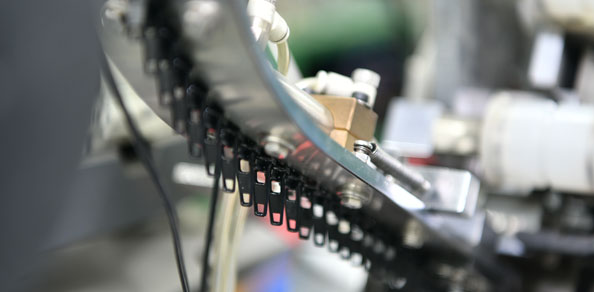

Zippers, also known as zip fasteners, are one of the most important auxiliary accessories in clothing and ranked first among the top ten inventions that have significantly impacted people's lives, according to the 1986 issue of the American magazine "Scientific American". Historically, the invention of zippers (with the first patent related to zippers emerging in 1851) dates back over 170 years. Like other industrial products, zippers have undergone a complex and lengthy evolution, transitioning from simple and unstable structures to today's sophisticated, clever, and convenient designs. From the initial single type of metal zipper with a single opening and closing function, zippers have evolved into a diverse range of metal, nylon, and injection-molded zippers, encompassing multiple categories, specifications, functions, and varieties. Zippers now present a rich and colorful array, with tremendous and profound changes in their materials, performance, structures, and uses compared to their original designs. They convey increasingly rich content, find application in an increasingly wide range of fields, and carry increasingly strong cultural connotations...

From the ingenious idea of solving the problem of putting on and taking off women's high-heeled boots to its widespread application in clothing, bags, and other fields, today's zippers are not limited to the traditional concept of opening and closing functions. They also possess new functions such as practicality, fashionable design, style narration, and aesthetic expression. In the industrial era, modern clothing is mainly dominated by "ready-to-wear" garments, with non-ceremonial clothing occupying most daily scenarios. The invention of zippers, along with the subsequent advancements in fabric and manufacturing methods, has gradually diverged global fashion trends and daily dress codes from traditional clothing. Especially driven by post-war denim and punk styles, zippers have directly become one of the most important functional accessories in clothing, thereby ushering in the era of personalization in fashion trends.

Zippers represent the convergence of aesthetic design and industrial design. Throughout the thousands of years of human clothing history, auxiliary materials such as ropes and buckles have carried people's aspirations for beauty. In the past century, the emergence of zippers has provided a new medium for humans to seek new expressions of individuality in clothing. Zippers and modern clothing design blend together, complementing and colliding with each other. As crucial opening and closing connectors, zippers' non-destructive operation enhances the restorability and integrity of garment pieces. Their external form also aligns well with the unity and symmetry of clothing, further conveying the beauty of clothing structure and lines. The diversity in material, color, structure, and style of zippers offers infinite possibilities for innovative combinations in different garments. For example, the small and concealed nature of invisible zippers can give traditional clothing greater plasticity, allowing traditional elements to be integrated into modern fashion trends.

"Small zippers embody great wisdom." Zipper manufacturing is a symbol of a country's industrial strength. The disciplines involved in zipper manufacturing can be directly traced to 37 existing disciplines in China, including 12 first-level disciplines. It can be said that the modern zipper manufacturing industry is supported by an entire industrial system, which is a multidisciplinary intersection of materials science, mechanics, and chemistry. It is a microcosm of the high-level development of China's civilian industry.

02

The Rise, Prosperity, and Dominance of Zippers in China

In the 1920s, zippers were introduced to China through military imports, primarily used in military uniforms. Foreign trading companies, mostly Japanese, marketed zippers in Shanghai. Amid a large-scale boycott of Japanese goods in China, many Shanghai hardware enterprises entered the domestic zipper industry to revitalize domestic products. One such enterprise, the "Wuxiangxin" Hardware and Military Uniform Factory, was the first to establish a zipper factory, becoming the first recorded zipper production enterprise in China. It even registered China's first zipper trademark, the "Iron Anchor Brand." With the increasing demand for zippers as military supplies due to the war, the zipper industry in Shanghai flourished. However, due to the war, the nascent domestic zipper industry quickly declined. During the most turbulent times, amidst the vast and fragmented waves of historical change, the zipper industry was like a grain of millet blown by the wind to fall on torn land, deeply sensing the mission entrusted by the times. "Today's businessmen hold the power to determine the survival and prosperity of our nation." The birth of zippers in China was motivated by a profound sense of patriotism and a desire to serve the country, making it an industrious sector with integrity and backbone.

During the period of socialist exploration in New China and the turmoil of the Cultural Revolution, the spark of China's zipper industry quickly reignited amidst the strategic layout of the country's priority on industrial development. The state-owned zipper industry rapidly expanded, but its development was still struggling due to the complex conditions of the time, including limited funds, technology, and markets.

The Third Plenary Session of the Eleventh Central Committee of the Communist Party of China marked the beginning of China's reform and opening-up. The dawn of the market economy melted the snow on the ice fields, and countless streams converged into a surging force, giving rise to private industries like bamboo shoots after a rain. In the southeastern coastal provinces, the zipper industry was the first to set sail. Against the backdrop of relaxed mainland policies, open Hong Kong market channels, and the introduction of Taiwan machinery and equipment, the domestic zipper industry, leveraging the favorable winds of the times, became self-reliant and grew rapidly in an unrefined manner. It swiftly established a modern zipper production and sales system that integrated the entire industrial chain, from raw material and auxiliary material supply, professional equipment research and development, zipper manufacturing, to technical quality standards.

From accompanying to running alongside to leading, Chinese zippers have embarked on a path of transformation through independent innovation. Over the past four decades of expansion and increment, Chinese zippers have never ceased their pace of innovation, systematically advancing in manufacturing innovation, material innovation, and product innovation. From innovations in basic zipper materials to the development of multi-in-one smart equipment, the combined technological efforts of more than 200 equipment R&D enterprises are sufficient to achieve a qualitative leap for this niche product. Multiple leading zipper enterprises have cooperated with Donghua University, a prestigious institution in textile and apparel, to enhance their sustainable innovation capabilities through industry-academia-research cooperation and strengthen the transformation of innovation outcomes. With the simultaneous advancement of multiple combined innovation matrices, including systematic integration innovation, collaborative innovation, and enterprise-level independent innovation, the innovation efficiency of enterprises has been greatly improved, innovation outcomes have continued to emerge, and endogenous driving forces have been continuously enhanced.

03

From a development perspective, examining the new changes in domestically produced zippers,

In recent years, China's manufacturing has achieved qualitative breakthroughs in transformation and upgrading. High-tech manufacturing industries such as Chinese chips, large aircraft, new energy vehicles, quantum communications, heavy equipment, and high-speed railways have led us out of the shackles of being a "low-end manufacturing factory." Chinese manufacturing is ushering in a new historical transformation, which has also prompted developed economies such as the United States and Europe to encircle, pursue, and block us, attempting to halt China's advancement upstream in the value chain. Therefore, as consumers, we should give Chinese manufacturing more confidence, respect, and tolerance. The arduous journey of Chinese manufacturing's independent creation over the past four decades reflects the solid strides made by the national zipper industry towards high-quality development.

In the early days of reform and opening-up, China's civilian industry focused on addressing the quantitative issues of "whether it exists" and "whether it is sufficient." Product manufacturing was in the "imitation" stage, prioritizing quantity. The huge market bluespace led enterprises to neglect quality control, resulting in low-end and inferior quality industrial products in China. Similarly, Chinese zippers had common quality issues such as jamming, bursting, and tearing, which was an undeniable fact.

Since China's accession to the WTO, more and more "Made in China" products have been sold globally. The rapid increase in China's export scale and the stringent quality requirements of international buyers have forced Chinese enterprises to improve internally. With the introduction of advanced equipment from Taiwan, Japan, South Korea, and Germany, domestic zippers have reached a new level in quality and efficiency. Functional quality issues have been basically resolved, and enterprises have begun to increase investment in innovation, strengthen quality management, and optimize marketing services, gradually shaking off the path dependence of low-end industries and launching an offensive into the mid-to-high-end market.

From accompanying to running alongside to leading, Chinese zippers have embarked on a path of transformation through independent innovation. Over the past four decades of expansion and increment, Chinese zippers have never ceased their pace of innovation, systematically advancing in manufacturing innovation, material innovation, and product innovation. From innovations in basic zipper materials to the development of multi-in-one smart equipment, the combined technological efforts of more than 200 equipment R&D enterprises are sufficient to achieve a qualitative leap for this niche product. Multiple leading zipper enterprises have cooperated with Donghua University, a prestigious institution in textile and apparel, to enhance their sustainable innovation capabilities through industry-academia-research cooperation and strengthen the transformation of innovation outcomes. With the simultaneous advancement of multiple combined innovation matrices, including systematic integration innovation, collaborative innovation, and enterprise-level independent innovation, the innovation efficiency of enterprises has been greatly improved, innovation outcomes have continued to emerge, and endogenous driving forces have been continuously enhanced.

Refining product capabilities through innovation and driving brand power with product capabilities. From benchmarking international zipper brands to setting new standards for "Quality Zippers, Made in China," domestic zippers adhere to the innovation concept of continuous advancement and iteration, consistently creating high-quality products. Under a microscope, we see SBS (Sunshine) contributing to China's aerospace achievements, demonstrating its product capabilities; SAB (Weixing) aiding Anta in crafting the "Champion Dragon Suit" for the Winter Olympics, showcasing its brand power; YCC (Donglong Clothing) solving the century-old problem of fabric puckering with wrinkle-resistant zippers; HSD (Huashengda) utilizing digital twins to create trendy and avant-garde zipper adaptation solutions; 3F (Fuxing) winning a gold medal at an international design competition for its antistatic zippers; and KEE (Kaiyi) earning a Red Dot Best of the Best Award for its fabric-free zippers... In recent years, avant-garde products such as slider-track zippers, high-airtightness zippers, color-changing zippers, multi-colored zippers, and bio-based zippers have emerged in an endless stream, continually satisfying the "whimsical ideas" in the field of fashion design.

In the "competition through learning and catching up" amidst saturated markets, as the textile and apparel market growth slows down, China's zipper industry has also entered a period of profound adjustment, with the industrial landscape constantly evolving and intensifying innovation "internal competition" among enterprises. Leading domestic zipper enterprises, represented by SBS (Sunshine Zipper) and SAB (Weixing Zipper), are initiating a new wave of transformation and upgrading.

Enterprises are venturing overseas in clusters, supporting Chinese apparel in exploring and expanding new markets. In recent years, with the in-depth adjustment of global industrial chains, there has been a notable trend of China's textile and apparel industry shifting to Southeast Asia. On the other hand, amid the demand for security and resilience in the global textile and apparel supply chain, the diversified layout of supporting suppliers is imperative. Domestic zipper brands, represented by HSD (Huashengda Zipper), have taken the lead in going overseas by establishing production bases in Southeast Asia and deeply cultivating the local market. Localized services have greatly enhanced the level of specialization and quality of zipper supporting services for the textile and apparel industry in Southeast Asia and other regions. Following HSD's lead, a large number of domestic zipper enterprises such as SAB and SBS have followed suit and ventured overseas. Southeast Asia is gradually emerging as a landscape dotted with Chinese zipper enterprises, playing a crucial supporting role in the international expansion of Chinese apparel.

Digital and intelligent transformation, seeking "new plasticity" for change across industries. With the in-depth development of digitization and intelligence, there is a new direction for fusion innovation in zipper manufacturing. Digital enablement has become a new trend among domestic zipper enterprises, with Weixing Zipper taking the lead in this regard: using the "1+N+N" architecture (1 digital platform for apparel accessories, N supplier and garment factory supply chain platforms, N digital scenario applications) to horizontally connect the entire value chain from suppliers to customers, enhancing digital collaboration throughout the entire product design, research and development, procurement, production, marketing, and service process, enabling rapid and flexible delivery of customized orders, and providing a practical digital transformation solution for Chinese zippers and even Chinese apparel.

Quality upgrading again, building the foundation for "Quality Zippers, Made in China." In a market environment where not advancing means regressing, quality is the lifeblood of enterprises. The main focus of China's zipper industry has been a prolonged battle for quality upgrading. Over the past decade or so, driven by leading enterprises, the overall quality of Chinese zippers has seen tremendous improvement. Nowadays, even low- to mid-range zippers do not suffer from basic quality issues such as chain bursts or missing teeth, while physical performance indicators (such as flat tensile strength, load cycles, color fastness, slider self-locking strength, and smoothness of zipping) have been significantly enhanced. China is now at the forefront globally in areas such as fabric tape shrinkage control, dyeing accuracy, surface detail treatment, and the development of high-strength metals and alloys. China's zipper quality standards are updated every three years with minor revisions and every five years with major ones. Patented innovative products are introduced at a rate of 20% annually, with a market penetration rate of over 85% in the high-end brand market.

Green and low-carbon initiatives lead the new trend of sustainable development. In recent years, the sustainable fashion trend has swept the apparel industry. With China's "dual carbon" (carbon peaking and carbon neutrality) goals entering the express lane, apparel brands are also accelerating the creation of green supply chains. The trend towards green practices has also gained momentum in the zipper industry, as Chinese zipper manufacturers have deeply implemented the concept of green development, initially forming a system in green product design, green material research and development, and green manufacturing layout. Currently, domestic zipper brands have obtained certifications such as OEKO-TEX 100 (an international eco-label for textile products), BSCI (Business Social Compliance Initiative), and SEDEX (Supplier Ethical Data Exchange). Many enterprises have joined international climate initiatives such as the Fashion Industry Charter for Climate Action. In terms of products, green zippers such as biodegradable bio-based zippers and recyclable zippers are emerging in an endless stream. Efforts are also being actively made in green manufacturing and clean energy. For instance, major zipper enterprises are constructing rooftop photovoltaic projects to diversify and clean up energy sources. Weixing Zipper has significantly improved energy utilization through heat recovery, centralized production, and equipment upgrades, and has released sustainable development reports for more than a decade consecutively. Sunshine Zipper has achieved zero effluent discharge through advanced technologies such as waterless dyeing and water recycling treatment... These practical measures fully demonstrate the vibrant green development of China's zipper industry, which is full of vitality and continues to evolve.

04

Contributing the strength of "national zippers" to building a powerful apparel country

The Chinese apparel industry has set forth its development vision and goals for 2035: By the time China basically achieves socialist modernization, it aims to transform the Chinese apparel industry into a powerful apparel country that promotes, innovates, and contributes to the development of the global fashion industry, becoming a major driver of world fashion technology, an important leader in global fashion, and a strong promoter of sustainable development.

China's zipper industry has flourished alongside the rise of the country's apparel industry and is now welcoming new opportunities and challenges amidst the technological, fashionable, and green transformations of the Chinese apparel industry. The 2035 development vision for China's apparel industry has embarked on a new journey towards becoming a powerful apparel country, and the high-quality development of domestic zippers is inevitably an important component of this journey. In the new industrial development cycle, China's zipper industry will continue to prioritize quality, closely follow apparel development trends, implement the green and low-carbon development concept, and persist in enhancing the technological innovation capabilities of the industry, contributing the strength of national zippers to the goal of building a powerful apparel country.

Conclusion:

There are still some companies that take a "carving marks on a moving boat" approach, staying away from and dismissing Chinese zippers. The reasons for this are twofold: on the one hand, they are insensitive to the progress of "Made in China" and still hold the stereotype that "cheap things are not good"; on the other hand, they blindly admire foreign brands, lacking rational cognition and a developmental perspective.

In recent years, at the China International Fabric and Accessories Exhibition, SAB's booth stands on one side, facing off against YKK (a long-established Japanese zipper brand) on the other, with comparable crowds at both. Booths of domestic zipper brands such as SBS, HSD, CMZ, YCC, 3F, HEHE, YQQ, THC, GCC, and JKJ are also bustling with people. More and more apparel brand enterprises are understanding, choosing, and trusting Chinese zippers. Customers who have truly cooperated with them cannot escape the "irresistible truth" of their high cost-performance ratio. The evolution of Chinese zippers is a testament to quality, technological breakthroughs, and service upgrades. On the path forward, Chinese zippers have always adhered to and practiced the original aspiration of revitalizing the national industry and the mission of building a powerful apparel country. In the future, against the backdrop of Chinese-style modernization and the construction of a powerful Chinese apparel industry, the Chinese zipper industry will continue to innovate and forge ahead, striving to write a new chapter in industrial upgrading and development!

Reprinted from: China National Garment Association